As coronavirus spreads throughout the United States, millions of panicked Americans have been hoarding everything from canned food to absurd amounts of toilet paper. Images of empty store shelves are compounding the situation, as worries over shortages amid a potential quarantine have added to the surge in purchases.

According to the nation's largest retailers, meat producers and dairy farmers however, there's plenty of food in the country; the problem is that the supply chain wasn't designed to handle this type of nation-wide surge in purchases and is now scrambling to catch up, reports the New York Times.

Industries that are calibrated to supply consumers with just enough of what they need on a given day cannot keep up with a nationwide surge of relentless shopping fueled in large part by fear. -NYT

As distributors and retailers struggle to restock shelves with a sudden demand for canned soup and oat milk, industry officials insist that these are temporary problems.

"There is food being produced. There is food in warehouses," said North American Meat Institute CEO, Julie Anna Potts. "There is plenty of food in the country."

Costco COO Ron Vachris said in a Saturday interview "Our stores are getting stocked every day," adding "Transportation is functioning, our suppliers are working around the clock and the flow of goods is strong."

Notably, hot dog orders at Costco and Walmart have increased by as much as 300% according to meat suppliers - with some hot dog plants adding Saturday and Sunday shifts, and are shipping Memorial Day stockpiles to meet the surge in demand. Hot dog makers say they have a year's supply of ingredients such as garlic, according to the report.

Meanwhile, the National Chicken Council says they aren't seeing any disruptions in production - and that "ample surplus supplies of chicken" are currently in cold storage - 950 million pounds worth, according to government data.

None of this matters to shoppers facing empty shelves right now, however.

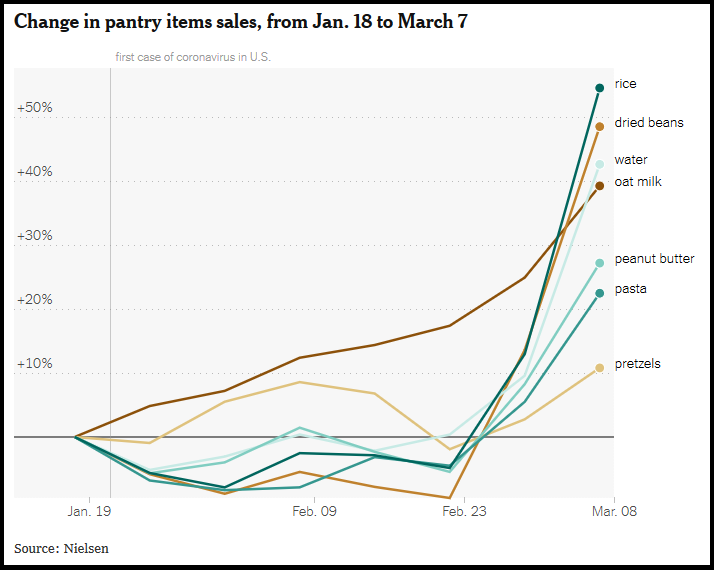

The panicky buying is testing the food system’s capacity in the near term. Over the past few weeks, sales of rice have increased more than 50 percent, according to data from the research firm Nielsen. Canned meat is up more than 40 percent. And sales of other essentials like beans, pasta, peanut butter and bottled water have also risen substantially, with a sharp spike this month. Kroger told its suppliers that demand had surged 30 percent across all categories in recent days. (For comparison, the company’s sales for all of last year rose about 2 percent.) -NYT

Another factor in helping to restock store shelves is shifting the food supply from closed restaurants, school cafeterias and college campuses.

"The food is there. It’s just going into different spots," according to FreshDirect CEO David McInerney. "Cruise ships are not using up all of the avocados. We have a giant surge of avocados."

The hoarding began around two weeks ago. According to the Times, shortages in hand sanitizers and wipes "set off a wave of panic buying that spread in recent days to include bread, canned goods, milk and frozen food." Perhaps a more plausible explanation is that the reality of a potentially protracted home-quarantine combined with people who don't want to shop at a store with aerosolized, three-hour hang-time coronavirus in the aisles has driven Americans to stock up before it hits en masse.

Ramping up

Despite there being 'enough food' - there are logistical issues to increasing production, such as the 50-days or longer it takes for chickens to go from egg to mature bird to store shelves.

For some chicken suppliers, the process takes even longer, depending on the type of bird.Across the industry, “you’re talking about 50 days to get to a customer,” said Matthew Wadiak, who runs Cooks Venture, a chicken supplier based in Arkansas and Oklahoma. “Fifty days ago, we didn’t know this was even on the horizon. There was essentially no way to plan for it.”..."It’s clear that the modern supply chain, for all its efficiency and speed, is not equipped to deal with this kind of surge." -NYT

Amazon's algorithms, for example, have been designed to provide near-perfect estimations of exactly how much inventory warehouses or particular stores must keep on hand during a typical week - but they're unable to cope with this type of exogenous event leading to bare shelves in such a short period of time.

"When the shelf is emptied in the course of 24 hours and the safety stock was built intent upon protecting a week or two of demand, you get this tremendous dislocation," said Columbia Business School director of retail studies Mark Cohen.

"The trouble is that the hoarding hasn’t abated. We’re just seeing the very beginning of this kind of behavior," he added. "The question is: How long will it take for industry to catch up?"